New Technique for Bridge Foundation Protection Enhancing Bridge Anti-washout Capacity

- Date:2022-10-18

- Update:2024-01-31

- Department:Transportation Technology Research Center

To enhances the anti-washout capacity of bridge foundations, the Institute of Transportation, MOTC has researched and developed a new bridge foundation protection technique with the combined use of tribar armor and geotextile, which received an invention patent from the Intellectual Property Office, Ministry of Economic Affairs in April 2022. It was provided to the Freeway Bureau, MOTC. for application in the 2022 bridge maintenance operations in order to enhance the bridge foundation anti-washout capacity, thereby ensuring bridge safety and safe passage of the public.

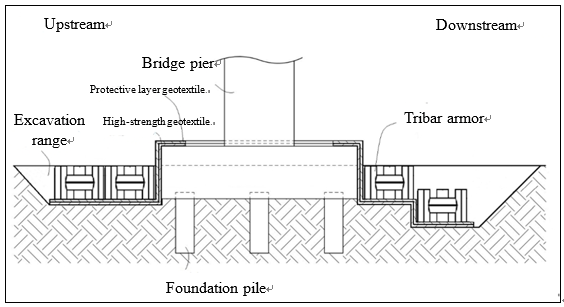

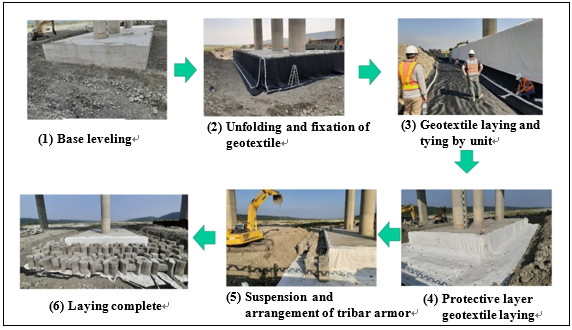

Railway and road cross-river bridge foundations often have the problem of exposure due to river washout, which affects the safety of bridges. In the past, bridge management units stacked rigid tribar armor around the bridge foundation to enhance the anti-washout capacity. However, the bed material under the tribar armor was still hollowed out after long-term river washout. Consequentially, inclination, loss, or destruction of paved tribar armor resulted, depriving the bridge of its protection effectiveness. In view of this, the Institute of Transportation, MOTC, has researched and developed a new protection technique through the combined use of tribar armor and geotextile in order to alleviate the problem of the washout of bed material at the bottom of tribar armor. In addition, a series of hydraulic model tests at testing room, and field tests at Freeway No. 3 on the Dajia River have been conducted. Results show that the protective plan involving the use of rigid tribar armor supplemented by flexible geo-textile does indeed mitigate bridge foundation washout and enhance the stabilizing effect of tribar armor.

A geotextile is made from polypropylene fiber (PP) using a weaving technique. It is a planar material featuring high strength, high permeability, corrosion resistance, ultraviolet resistance, non-pollution, flexible material that facilitates construction, etc. This technique is in reference to the Caisson-type wharf design in port engineering and used the concept of geotextile to prevent the loss of backfill. Compared to existing tribar armor pavement construction technique, this method only added a layer of geotextile below the existing tribar armor. This technique has been proven to demonstrate constructability while reducing the loss or inclination of tribar armor. The area requiring maintenance in the future has also decreased by about 90%, reflecting the effects of extending the service life of bridge foundations and reducing the frequency of maintenance. This technique design concept also demonstrates technical innovativeness, for which it has received an invention patent from the Intellectual Property Office, Ministry of Economic Affairs. (Patent No. I759792).

Through the promotion and exchange of this technique and assistance in budgeting and construction planning, the Freeway Bureau, MOTC has currently applied the technique in the 2022 bridge maintenance operations and has conducted related bridge foundation protection. It will enhance the anti-washout capacity of bridges and ensure the safety of bridges and the safe passage of the general public.

Figure 1: Schematic diagram of tribar armor + geotextile paving cross-section protection technique

Figure 2: Schematic diagram of tribar armor + geotextile paving cross-section protection technique

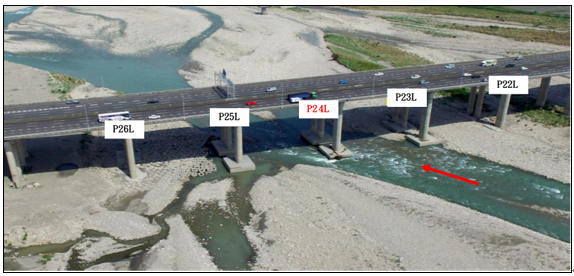

Figure 3: River conditions at the test bridge site (P24L) prior to the tribar armor + geotextile laying protection technique

Figure 4: Comparison of the test bridge site (P24L) after typhoon flood washout with the washout situation of a nearby bridge in 2021