The Creation and Application of the Track Fastener Defect Identification System

- Date:2020-03-03

- Update:2024-01-31

- Department:Transportation Technology Research Center

The Institute of Transportation, MOTC (IOT) and the Taiwan Railways Administration, MOTC (TRA) cooperated to develop the track fastener defect identification system in 2019. Railway track fastener automatic identification and analysis are carried out using cameras coupled with artificial intelligence (AI) deep learning methods and fastener defect inspection operations are improved through advanced technology, thereby assisting in inspection work execution and enhancing its efficiency.

At present, the track fastener operations of TRA are conducted by manual visual inspections at night. However, manual visual inspections are limited by inspection vehicle speeds, inspection angles and other problems that cannot be addressed effectively and quickly. Therefore, the TRA requested the IOT to formulate improvement plans using advanced technology. The IOT subsequently proposed the Track Fastener Image Identification System to assist in conducting inspection tasks by means of AI automatic identification, hoping to enhance efficiency and effectively resolve problems such as the inspection limitations and visual fatigue of inspectors.

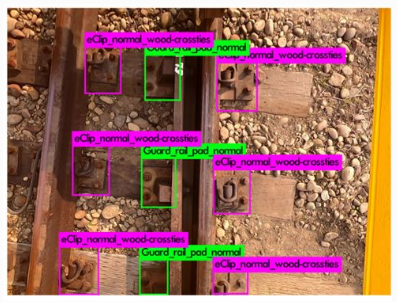

The track fastener image extraction equipment constructed by the IOT includes cameras and lighting devices. Within the jurisdiction of the TRA, one railway track section was selected to obtain clear images that AI can adequately identify. Through image tagging and the adoption of Yolo v3 AI identification software, deep learning model training was carried out to create the Fastener Image Inspection and Automatic Identification System, which can be used to detect railway track fasteners that have come off. For the image extraction part, sports-type cameras (GoPro) are adopted at present for video recording. Night inspection vehicles at the speed of 30km have recorded images of track fasteners of railway which length is more than 70km, with a fastener image identification accuracy of 86.7%. In the future, further improvements will be made, hoping to ultimately achieve the purpose of replacing manual inspections with railway track fastener AI image identification.

In addition, in order to enable inspectors to conveniently detect defective fasteners for repair, a system including cloud storage, identification and search functions have been developed, allowing Google Map to display and position defective fasteners pending repair by TRA personnel. The system (equipment included) about NT$1 million in cost can assist TRA track maintenance section personnel in inspecting track fasteners, determining defects and engaging in positioning and repair; it can also be provided for use by railway maintenance and inspection units to enhance track inspection efficiency, facilitate maintenance and repair, and improve the safety of tracks.

|

|

| Track fastener image automatic identification |

Left: a defective fastener Right: a normal fastener |

Figure 1 Track fastener defect automatic identification

Figure 2 Track fastener defect positioning

File Download

- 20200303-news.pdfCounter:258